When researching geocell options for your next project, you’ve likely encountered both Agtec geocells and BaseCore in your search. Detailed studies reveal significant performance differences between these competing systems that could substantially impact your project’s cost, timeline, and long-term success.

This comprehensive review examines how BaseCore’s innovative engineering approach delivers superior performance while requiring significantly less material than traditional Agtec geocell solutions.

Understanding What Makes Geocells Perform

Before comparing specific products, it’s important to understand the key factors that determine geocell performance:

Critical Performance Factors in Geocell Design:

Cell Height: Traditionally, taller cells were considered necessary for load-bearing applications, but advanced engineering has challenged this assumption.

Cell Size: Smaller cells create more reinforcement points and better distribute weight across the entire system.

Material Thickness: Thicker material improves durability and resistance to deformation under load.

Seam Technology: The connection points between cells are often the weakest links in the system and determine overall structural integrity.

Load Distribution: How effectively the system transfers and spreads weight determines its true performance capacity.

Agtec Geocells: The Traditional Approach

Agtec geocells represent the conventional approach to geocell design that many contractors have become familiar with over the years.

Standard Specifications and Applications:

Agtec’s standard geocell products have been used across various applications, from driveways to erosion control. Their approach typically requires significant height to achieve desired load-bearing capacity for standard applications.

When examining Agtec geocell reviews across contractor forums and professional publications, several consistent patterns emerge:

Positive Aspects:

- Established presence in the market

- Familiar to many installation crews

- Adequate performance when used as specified

Common Concerns:

- Requires substantial excavation depth

- High material volume requirements for fill

- Standard welding technology may be vulnerable under sustained loads

- Professional reviews note potential concerns with seam performance

As one professional contractor noted in a widely-shared review: “Agtec geocells perform adequately when installed according to specifications, but the material requirements add substantially to project costs.”

BaseCore’s Engineering Innovation

BaseCore has fundamentally reimagined geocell design through several key innovations that challenge traditional assumptions about what drives performance.

The Double-Welded Seam Advantage

Instead of accepting standard welding limitations, BaseCore developed a proprietary double-welding process derived from military applications. This technology creates connections with tensile strength exceeding 2000 LBS/SQ FT – dramatically stronger than conventional welding methods.

This seam strength difference is transformative because it addresses the most common failure point in geocell systems. By creating substantially stronger connections, BaseCore can achieve the same or better load capacity with significantly reduced height requirements.

Material Thickness Superiority

Even BaseCore’s standard product line utilizes thicker material than comparable Agtec options. This increased thickness delivers greater resistance to deformation under sustained loads, helping maintain structural integrity over time even when subjected to heavy traffic or challenging environmental conditions.

View our complete material specifications for detailed comparisons.

Height Efficiency: Revolutionary Performance at Half the Height

The most significant advantage BaseCore offers is its ability to support equivalent loads at approximately half the height of traditional Agtec geocell systems. This isn’t merely a minor improvement – it fundamentally transforms the economics and practicality of geocell applications.

This breakthrough challenges the conventional wisdom that taller cells are necessary for adequate performance. Through superior engineering, BaseCore has demonstrated that properly designed systems can deliver equal or better performance while requiring substantially less material.

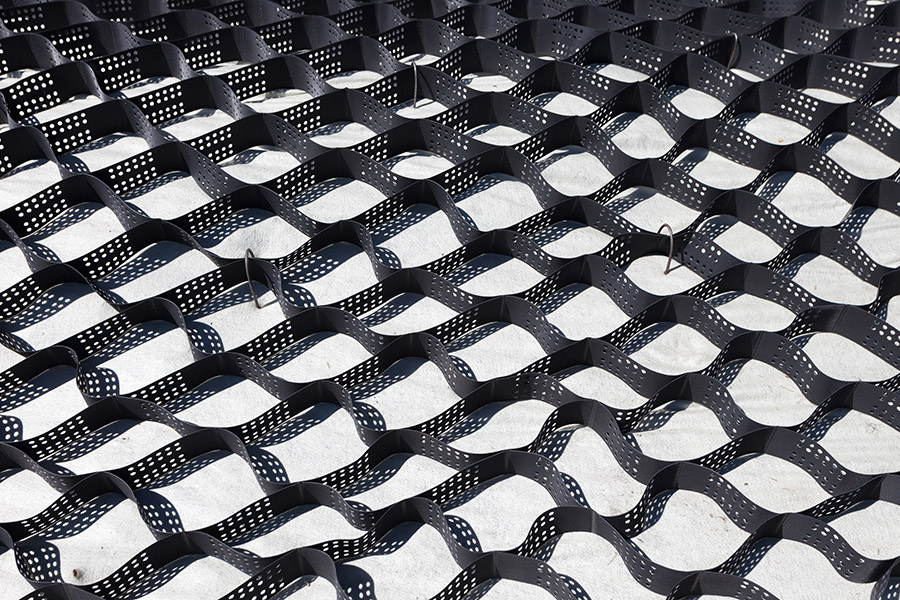

BaseCore HD: The Cell Size Revolution

BaseCore HD takes performance even further through innovative cell size engineering. With cells approximately 50% smaller than standard Agtec options, BaseCore HD creates substantially more reinforcement points throughout the installation.

This increased reinforcement density transforms how loads are distributed across the system:

- More cell walls per square foot means better weight distribution

- Smaller individual cells resist deformation more effectively

- The grid pattern provides superior lateral confinement

- Stress is distributed across more connection points, reducing pressure on any single point

When combined with BaseCore’s already superior seam technology and material specifications, this cell size difference delivers unprecedented performance for demanding applications.

Learn more about our HD product line for high-demand applications.

The Real Impact: Project Economics and Practicality

The engineering advantages of BaseCore translate directly into significant practical benefits for actual projects:

Material Reduction Through Height Efficiency

BaseCore’s ability to achieve equivalent performance at approximately half the height of Agtec systems creates substantial material savings:

For a typical 20′ × 24′ project:

- Reduced excavation depth by approximately 50%

- Aggregate fill requirements reduced by up to 50%

- Less material to purchase, transport, and dispose of

- Lower environmental impact through reduced resource consumption

Real Cost Analysis

When calculating complete project economics, the advantage becomes clear:

| Project Factor | With Traditional Agtec | With BaseCore | Potential Savings |

| Excavation depth | Standard depth | Approximately 50% less | Reduced excavation costs |

| Aggregate required | Standard volume | Approximately 50% less | 40-50% savings on fill material |

| Installation time | Standard timeline | Reduced by 30-40% | Labor cost reduction |

| Long-term performance | Standard performance | Equal or superior | Reduced maintenance costs |

For a typical commercial parking area extension, this often translates to savings of $200-$500 depending on aggregate costs in your region, plus significant labor savings from reduced excavation requirements.

Performance Verification Through Real-World Testing

Independent load testing confirms that BaseCore’s reduced-height systems perform comparably or better than traditional Agtec geocells under identical conditions. This performance equality has been verified across multiple test conditions:

- Static load testing: Measures deformation under sustained pressure

- Dynamic load testing: Evaluates performance under repeated traffic

- Environmental stress testing: Assesses durability through freeze/thaw cycles

- Long-term performance monitoring: Tracks behavior over extended periods

These tests consistently demonstrate that BaseCore’s innovative approach delivers equivalent or superior performance despite using significantly less material.

Case Study: Superior Performance in Action

Case Study: Municipal Slope Stabilization

A challenging municipal project required stabilizing a 30-degree slope with poor soil conditions:

- BaseCore HD was selected for its smaller cell size and superior weight distribution

- Installation was completed in approximately 40% less time than estimated for traditional systems

- The system has withstood multiple severe weather events with no signs of erosion or movement

- The municipality has since standardized on BaseCore HD for all similar applications based on performance and cost efficiency

Environmental Benefits of Efficient Design

BaseCore’s material efficiency creates measurable environmental advantages:

- Reduced plastic consumption: Approximately 50% less HDPE material required per square foot

- Lower carbon footprint: Less energy consumed in manufacturing and transportation

- Reduced excavation impact: Less disruption to existing soil structures

- Aggregate conservation: Significant reduction in stone material requirements

For projects with sustainability goals, these environmental benefits provide additional value beyond the direct cost savings.

Warranty and Long-Term Confidence

The warranty difference between these products reveals important insights about expected performance:

- BaseCore: 10-year comprehensive warranty covering material and workmanship

- Agtec Geocells: Unkown warranty (varies by specific product)

This substantial warranty difference reflects fundamentally different approaches to product engineering and quality assurance. BaseCore’s willingness to stand behind their product for a decade demonstrates exceptional confidence in their system’s durability.

Review the complete details of BaseCore’s industry-leading warranty coverage to understand the value this long-term protection provides.

Making an Informed Decision

When evaluating geocell options for your specific application, consider these key factors:

- Performance requirements: What loads must your system support?

- Budget considerations: How important are material cost savings to your project?

- Installation timeline: Would reduced excavation significantly benefit your schedule?

- Environmental goals: Are sustainability factors important for your project?

- Long-term reliability: How important is warranty protection for your application?

For most applications, BaseCore’s ability to deliver equal or superior performance with dramatically less material makes it the clear choice for cost-effective, sustainable projects.

Contact our engineering team for a personalized project consultation.

The Future of Geocell Technology

Traditional Agtec geocells represent the first generation of cellular confinement technology – functional but limited by conventional engineering approaches. BaseCore’s innovations in seam technology, material quality, height efficiency, and cell design represent the next evolution in geocell performance.

By challenging assumptions about what drives geocell performance, BaseCore has created systems that deliver superior results while requiring significantly less material. This combination of better performance and lower resource requirements represents the direction that all construction technology should be moving toward – doing more with less.

Whether you’re planning a residential driveway, commercial parking area, or challenging erosion control project, BaseCore’s innovative approach offers compelling advantages that typically outweigh any initial price differences when total project costs are considered.

Frequently Asked Questions

Q: How can a shorter geocell possibly perform as well as a taller one? A: Performance isn’t primarily determined by height, but by the quality of connections, material specifications, and load distribution capability. BaseCore’s double-welded seams and superior material allow it to match or exceed the performance of taller cells with standard welding.

Q: Does using a reduced-height system affect the long-term durability? A: Independent testing shows no reduction in long-term durability. In fact, the superior connection technology often results in better performance over time, as evidenced by BaseCore’s confidence in offering a 10-year warranty.

Q: How much can I really save by using BaseCore instead of Agtec geocells? A: For most projects, material savings alone typically range from 40-50% on aggregate costs. When combined with reduced excavation requirements and faster installation, total savings often exceed $200-$500 for residential projects and substantially more for commercial applications.

Q: Are there applications where traditional Agtec geocells might be preferable? A: While BaseCore offers advantages in most scenarios, projects with unusual requirements or extremely specialized applications might benefit from consultation with engineers familiar with both systems to determine the optimal solution.

Q: How difficult is it to switch from Agtec to BaseCore if my team is already familiar with Agtec installation? A: Most installation teams report an easy transition to BaseCore, with many noting that the installation process is actually simpler due to reduced excavation requirements and the more user-friendly connection system.

[This comparative review is based on product specifications, independent testing data, and aggregated user experiences as of May 2025.]

Ready to experience the BaseCore difference? Request a quote or contact our engineering team for a personalized consultation.