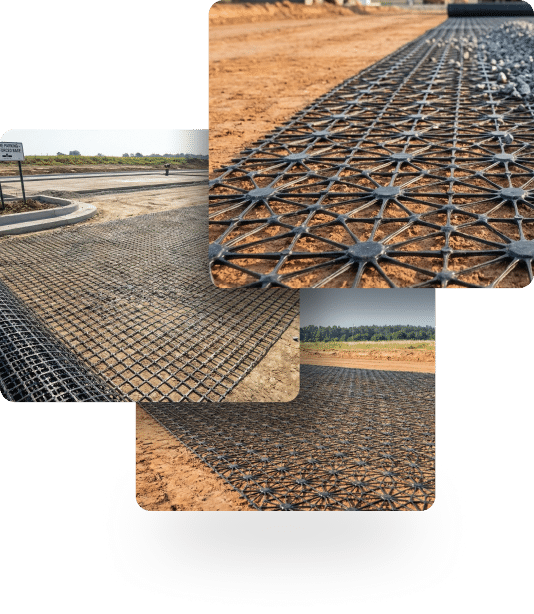

BaseGrid™ Geogrids

High-strength biaxial and multi-directional geogrids that reinforce road bases, stabilize foundations, and extend pavement life. Pair with BaseCore™ geocells for a complete ground stabilization system — or deploy independently for base reinforcement across roads, parking areas, railways, and slopes.

Foundational BaseGrid™ Benefits

Even Strength in Every Direction

Our multi-directional geogrids feature continuous ribs arranged in 12 orientations, delivering near-uniform tensile performance across all load angles. Unlike biaxial grids that are strong in only two directions, multi-directional design handles the unpredictable, multi-angle loads that real-world traffic produces.

Less Base Material Required

BaseGrid™ geogrids distribute loads more efficiently across weak subgrades, reducing the required aggregate base thickness by up to 40-50%. Less material to haul, spread, and compact means lower cost and faster construction — especially on remote sites where aggregate is expensive.

Roads That Last Longer

Geogrid reinforcement at the base-subgrade interface reduces differential settlement and prevents aggregate contamination. The result is a stiffer, more resilient base that extends pavement service life and reduces maintenance frequency on paved and unpaved roads alike.

Build on What You Have

Soft clays, silts, and organic soils that would normally require removal and replacement can often be built on directly when geogrids distribute loads across a wider area. Reduce or eliminate costly over-excavation on poor subgrade sites.

Engineered for Harsh Environments

Manufactured from polypropylene (PP) with a minimum 2% carbon black content, BaseGrid™ geogrids resist UV degradation, hydrolysis, acid, and alkali exposure. Suitable for the widest range of soil chemistries and climatic conditions — from desert heat to subarctic freeze-thaw.

A Complete Stabilization System

Use BaseGrid™ as the base reinforcement layer beneath BaseCore™ geocell panels for maximum load-bearing performance. The geogrid reinforces the subgrade interface while the geocell confines surface aggregate — two mechanisms working together for the strongest possible unpaved surface.

Unroll, Overlap, Build

BaseGrid™ geogrids ship in compact rolls, unroll directly onto prepared subgrade, and require no special equipment or adhesives. Overlap adjacent panels, place aggregate, and compact. Large areas can be covered quickly with minimal crew and equipment.

Third-Party Tested & Certified

All BaseGrid™ geogrids are tested to international standards including GB/T 15788 (wide-width tensile test) and GB/T 17689 (plastic geogrids). CNAS-accredited laboratory test reports are available for every product grade to verify published performance values.

BaseGrid™ Product Lines

BaseGrid™ offers two geogrid product lines to match your reinforcement requirements. Both are manufactured from polypropylene using extrusion, punching, and stretching processes that create high-strength rib structures with excellent interlock characteristics.

Our project team will assess your subgrade conditions, traffic loads, and design life to recommend the right geogrid — or the right geogrid + geocell combination — for your specific application.

BaseGrid™ Biaxial (TGSG Series)

Best for: Road base reinforcement, parking lot foundations, railway subgrade stabilization, airport taxiways, and general load support applications where primary loading aligns with longitudinal and transverse directions.

How it works: Square-network structure formed by extrusion, stamping, and biaxial stretching creates high tensile strength in both the machine (longitudinal) and cross-machine (transverse) directions. The rigid junctions and open apertures interlock with aggregate, creating a mechanically stabilized layer that distributes loads and prevents base deformation.

Key Specifications:

| Property | TGSG 1515 | TGSG 2020 | TGSG 2525 | TGSG 3030 | TGSG 3535 | TGSG 4040 | TGSG 4545 | TGSG 5050 |

|---|---|---|---|---|---|---|---|---|

| Yield Force (longitudinal) | 15 kN/m | 20 kN/m | 25 kN/m | 30 kN/m | 35 kN/m | 40 kN/m | 45 kN/m | 50 kN/m |

| Tensile Force at 2% Elongation | 5 kN/m | 7 kN/m | 9 kN/m | 10.5 kN/m | 12 kN/m | 14 kN/m | 16 kN/m | 17.5 kN/m |

| Tensile Force at 5% Elongation | 7 kN/m | 14 kN/m | 17 kN/m | 21 kN/m | 24 kN/m | 28 kN/m | 32 kN/m | 35 kN/m |

| Longitudinal Yield Elongation | ≤15% | ≤15% | ≤15% | ≤15% | ≤15% | ≤15% | ≤15% | ≤15% |

| Lateral Yield Elongation | ≤13% | ≤13% | ≤13% | ≤13% | ≤13% | ≤13% | ≤13% | ≤13% |

| Width | 1–6 m | 1–6 m | 1–6 m | 1–6 m | 1–6 m | 1–6 m | 1–6 m | 1–6 m |

Custom specifications available by agreement.

BaseGrid™ Multi-Directional (DJDX Series)

Best for: High-traffic intersections, roundabouts, heavy industrial yards, mining access roads, areas with multi-angle loading, and any application where loads arrive from unpredictable directions. The next generation of geogrid technology — co-developed with Shandong University.

How it works: Continuous ribs arranged in 12 directions create tightly interconnected triangular structures that transfer loads in every orientation. Unlike biaxial grids (strong in 2 directions only), multi-directional geogrids deliver near-uniform stiffness and strength across all angles — with ≤10% deviation between any tested orientation (0°, 30°, 60°, 90°). The triangular aperture geometry also creates superior interlock with irregularly shaped aggregate, maximizing the soil-reinforcement bond.

Available in two specification series:

Series 1 — Defined by Secant Modulus at 2% Elongation

| Property | DJDX200 | DJDX300 | DJDX400 | DJDX500 | DJDX600 | DJDX700 |

|---|---|---|---|---|---|---|

| Control Secant Modulus at 2% Elongation | ≥200 kN/m | ≥300 kN/m | ≥400 kN/m | ≥500 kN/m | ≥600 kN/m | ≥700 kN/m |

| Control Secant Modulus at 5% Elongation | ≥190 kN/m | ≥285 kN/m | ≥370 kN/m | ≥470 kN/m | ≥560 kN/m | ≥660 kN/m |

| Max Relative Deviation (any direction) | ≤10% | ≤10% | ≤10% | ≤10% | ≤10% | ≤10% |

Series 2 — Defined by Control Tensile Strength

| Property | DJDX20-20 | DJDX25-25 | DJDX30-30 | DJDX35-35 | DJDX40-40 | DJDX50-50 |

|---|---|---|---|---|---|---|

| Control Tensile Strength | ≥20 kN/m | ≥25 kN/m | ≥30 kN/m | ≥35 kN/m | ≥40 kN/m | ≥50 kN/m |

| Max Relative Deviation (any direction) | ≤10% | ≤10% | ≤10% | ≤10% | ≤10% | ≤10% |

| Control Elongation | ≤13% | ≤13% | ≤13% | ≤13% | ≤13% | ≤13% |

Testing: All DJDX products are tested per GB/T 15788-2017 (wide-width tensile test) at 0°, 30°, 60°, and 90° orientations. CNAS-accredited test reports available.

Custom specifications and intermediate grades available by agreement.

BaseGrid™ Applications

The Complete System: Geogrid + Geocell

For maximum performance on weak subgrades and heavy-traffic applications, pair BaseGrid™ geogrids with BaseCore

geocell panels. The two products address different layers of the structural section:

Geogrid (bottom layer):

Placed directly on the prepared subgrade or separation geotextile. Reinforces the base-subgrade interface, distributes loads over a wider area, and prevents differential settlement. Acts as the foundation of the stabilization system.

Geocell (upper layer):

Placed above the geogrid layer and filled with compacted aggregate. Confines infill material to prevent lateral displacement under traffic. Creates the load-bearing surface that handles direct vehicle contact.

Together:

The geogrid strengthens the foundation while the geocell stabilizes the surface — a two-mechanism system that outperforms either product used alone, especially on sites with poor subgrade conditions and heavy traffic demands.