You’re Researching Geocells — Here’s What Actually Matters

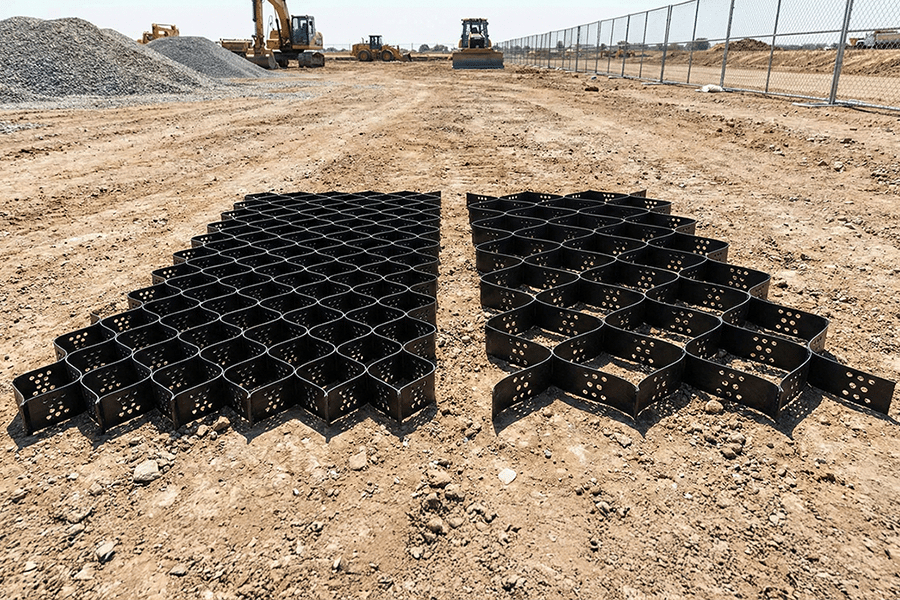

If you’ve been searching for “Agtec geocell,” you’re likely in the comparison phase of a buying decision. You’ve probably identified geocells as the right solution for your project — whether that’s stabilizing a gravel driveway, reinforcing a parking lot, controlling erosion on a slope, or preventing mud in a high-traffic area. Now you’re evaluating which product to buy.

That’s a smart approach. Not all geocells perform the same, even though they look similar at first glance. The differences in cell geometry, material thickness, seam strength, and the support you receive before, during, and after your project can mean the difference between a surface that performs for 20 years and one that fails within a few seasons.

This guide compares Agtec geocell products to BaseCore and BaseCore HD across every factor that matters to your project outcome. We’ll use publicly available specifications from both manufacturers, so you can verify everything yourself. Where Agtec doesn’t publish specific data, we’ll note that — because what a manufacturer doesn’t tell you can be just as important as what they do.

Who Makes These Products?

Understanding each company’s focus helps explain the product differences you’ll see in the specifications.

Agtec

Agtec (operated by Agriculture Solutions LLC, established 2007) is a broad agricultural supply company. Their product catalog spans frost blankets, row covers, weed barriers, shade cloth, geotextiles, and geocells. Geocells are one product category among many. Based on their published listings, Agtec’s geocell line is marketed primarily toward farm applications — driveways, animal enclosures, mud control, and light construction — and sold through their website, Amazon, and eBay.

Agtec’s geocell approach is retail and self-serve: you choose your depth from the product listing, add to cart, and figure out installation using the basic instructions provided on the product page. There’s no documented project consultation, custom panel sizing, or dedicated engineering support.

BaseCore

BaseCore (BaseCore USA, headquartered in Scottsdale, Arizona) is a geocell-focused manufacturer. Ground stabilization is their core business — not one category among dozens. They manufacture two distinct product lines (BaseCore standard and BaseCore HD), offer geotextile fabrics, geogrids, and PaveCore pavers as complementary products, and provide project management support from specification through installation.

BaseCore’s approach is consultative: you speak with a project manager who recommends the right product, cell depth, geotextile weight, infill material, and edge restraint based on your specific application. They offer custom panel sizing, detailed installation guides, and can connect you with experienced installers in your region.

This difference in business model — retail self-serve versus consultative project support — matters more than most buyers realize, especially on projects larger than a garden path.

Head-to-Head Specifications

Here’s where the product differences become concrete. All data below is sourced from publicly available product listings and documentation from agtec.com, agriculturesolutions.com, and basecore.co.

The Core Comparison Table

| Specification | Agtec Geocell | BaseCore Standard | BaseCore HD |

| Cell size (expanded) | 12.6″ x 11.3″ (320 x 287 mm) | 12.6″ x 11.3″ (287 x 320 mm) | 8.5″ x 7″ (180 x 218 mm) |

| Available depths | 2″, 3″, 4″, 6″, 8″ | 3″, 4″, 6″, 8″ | 2″, 3″, 4″, 6″, 8″ |

| Sheet thickness | 1.5 mm ±0.1 mm (~59 mil) | 60 mil after texturing | 65–75 mil after texturing |

| Double-welded seams | Not documented | No | Yes |

| Seam peel strength (ASTM D6392) | Not published | Published per ASTM D6392 | 88 lbf/in min (ASTM D6392); 190 lb long-term |

| Environmental stress crack resistance (ASTM D1693) | Not published | >1,500 hours | 7,000 hours |

| Panel sizes | 8.4′ x 27.4′ (230 sf) or 4.2′ x 27.4′ (115 sf) | Multiple sizes; 9′ x 18′ and others | Multiple sizes; 6.2′ x 9′, 8′ x 24′, and others |

| Custom panel sizing | Not available | Available | Available |

| Panel connection method | Zip-ties (~30 per panel) | Integrated connection system | Integrated connection system |

| Color options | Black only | Black, green, beige | Black, green, beige |

| Perforated/non-perforated | Perforated only | Both (non-perf made to order) | Both (non-perf made to order) |

| Warranty | 10 years — materials and workmanship defects only | 10 years — product and seam strength | 10 years — product and seam strength |

| Project consultation | Not documented | Yes — dedicated project managers | Yes — dedicated project managers |

| Installation guides | Basic on-page instructions | Detailed downloadable guides | Detailed downloadable guides |

| Sold through | agtec.com, Amazon, eBay | basecore.co, direct consultation | basecore.co, direct consultation |

Sources: agtec.com product listings (2024–2026), agriculturesolutions.com product pages, basecore.co product specifications and Universal Product Comparison data.

What the Specifications Actually Mean for Your Project

Numbers in a table only matter when you understand how they affect real-world performance. Let’s walk through the key differences and what each means for the surface you’re building.

Cell Size: Why Smaller Cells Confine Better

This is the most significant structural difference in this comparison. Agtec and BaseCore standard share the same cell dimensions: 12.6″ x 11.3″. BaseCore HD cells are 8.5″ x 7″ — roughly 40% smaller in area.

Why does this matter? Smaller cells confine infill material more tightly. When a vehicle tire applies force to a geocell surface, the load is distributed through the confined aggregate within each cell to adjacent cells. Smaller cells create more confinement points per square foot, which means better load distribution and less lateral movement of aggregate under pressure.

Think of it this way: imagine pressing your thumb into a bowl of marbles versus pressing into a jar of marbles. The jar (smaller container) resists the force better because the marbles have less room to shift sideways. The same principle applies to crushed stone confined in geocell walls.

For light-duty applications — a garden path, a pedestrian walkway, light erosion control — the larger cell size works fine. The loads are modest and the aggregate isn’t under significant stress. But as loads increase — delivery trucks on a commercial driveway, semi-trailers in a parking lot, heavy equipment on an access road — the tighter confinement of BaseCore HD becomes increasingly important to long-term surface integrity.

This cell size advantage also means that BaseCore HD at a given depth often delivers performance equivalent to a deeper standard-cell product. A 4-inch BaseCore HD can match the performance of a 6-inch product with larger cells in many applications. That translates to less excavation, less aggregate, and lower total project cost — even though the per-panel cost is higher.

Sheet Thickness: The Wall Strength Behind the Cell

Agtec’s published sheet thickness is 1.5 mm (approximately 59 mil). BaseCore standard runs 60 mil after texturing. BaseCore HD measures 65–75 mil after texturing — roughly 10–27% thicker than Agtec.

Thicker cell walls resist puncture better during installation and under service loads. They maintain structural rigidity longer under sustained heavy loads and repeated traffic cycles. And they’re more resistant to the slow creep deformation that can occur in HDPE under continuous pressure — exactly the condition in a parking lot where vehicles sit in the same spot for hours.

For a garden path with foot traffic, the difference between 59 mil and 75 mil walls is negligible. For a commercial parking lot handling delivery trucks five days a week for 15 years, that 27% increase in wall thickness becomes a meaningful factor in long-term performance.

Seam Strength: The Critical Spec Most Buyers Overlook

The seams — where HDPE strips are ultrasonically welded together to form the honeycomb — are the structural weak point in any geocell. If a seam fails, the cell opens up and loses its ability to confine aggregate. Under load, this creates a progressive failure: one seam opens, adjacent cells absorb the load, their seams are now overstressed, and the failure cascades.

BaseCore HD publishes seam peel strength at 88 lbf/in minimum per ASTM D6392 testing, with long-term seam strength reaching 190 lbs. These are among the highest published seam strength values in the geocell industry.

Agtec does not publish seam peel strength per ASTM D6392 on their product listings. They list tensile strength values (710 N/10cm for 2-inch, 1420 N/10cm for 4-inch, 2840 N/10cm for 8-inch), but tensile strength measures resistance to pulling the strip material apart — not the strength of the weld itself. These are related but different measurements.

Additionally, BaseCore HD uses double-welded seams, providing redundancy at the highest-stress points. If one weld is imperfect, the second weld maintains the connection. Neither Agtec nor most standard geocell products document double-welded seam construction.

Why this matters: You can’t verify what isn’t published. If seam strength data isn’t available, you’re relying on the manufacturer’s general quality claims rather than tested, documented performance values. For a walkway or garden bed, this may be an acceptable risk. For a commercial driveway or industrial yard where failure has significant cost implications, published performance data provides the engineering confidence that undocumented claims cannot.

Environmental Stress Crack Resistance (ESCR): Long-Term Durability

ESCR measures how long the HDPE material resists cracking under sustained environmental stress — the combination of mechanical load, temperature changes, and chemical exposure over years of service. It’s tested per ASTM D1693.

BaseCore HD achieves 7,000 hours in ESCR testing. BaseCore standard exceeds 1,500 hours. Agtec does not publish ESCR data on their product listings.

For reference, 1,500 hours of ESCR testing is generally considered adequate for moderate-duty geocell applications. The 7,000-hour result for BaseCore HD indicates exceptional resistance to stress cracking — significant for applications involving heavy loads, extreme temperatures, or chemical exposure (fuel spills in parking lots, fertilizer runoff on farm roads, etc.).

Beyond Specifications: The Support Comparison

Products don’t install themselves, and specifications don’t answer the question “which cell depth do I actually need for my driveway with a 26,000-pound delivery truck?”

What You Get With Agtec

Agtec’s support model is retail self-serve. Based on their published product listings and website:

- Product selection: You read the product descriptions and choose your depth based on general guidelines on the product page (e.g., “4” Geocells: Recommended for standard traffic areas, such as most gravel roads and driveways”).

- Specification guidance: The product pages list recommended geotextile weights (3.2 oz woven for 2–3″ geocells, 4.5 oz non-woven for 4″ geocells, 6–8 oz for 6–8″ geocells) and anchor stake sizes (10″ J-hooks for 2–3″, 18″ for 4–6″, 24″ for 6–8″ and slopes).

- Panel connection: Zip-ties (~30 per panel) and J-hook rebar stakes (~18 per panel), sold separately.

- Installation instructions: Brief text instructions on the product page: stake out, cut if necessary, fill with material, rake level.

- Custom sizing: Not available. Two panel sizes: 8.4′ x 27.4′ (230 sq ft) or 4.2′ x 27.4′ (115 sq ft narrow).

This approach works for straightforward DIY projects where you’re comfortable making specification decisions yourself. If you know your loads, understand your soil conditions, and are experienced with ground stabilization, you may not need hand-holding.

What You Get With BaseCore

BaseCore’s support model is consultative:

- Dedicated project managers: You speak with someone who has helped thousands of similar projects succeed. They ask about your specific loads, soil conditions, site challenges, and timeline — then recommend the right system.

- Specification guidance: Your project manager recommends cell depth, product line (standard vs. HD), geotextile fabric weight (6–12 oz non-woven for load-bearing applications), infill material (#57 crushed stone with 15–20% fines for most applications), and edge restraint options (concrete curbs, corten steel edging, pressure-treated wood, or flush excavation).

- Custom panel sizing: Panels can be manufactured to specific dimensions that minimize waste on your particular site layout. Standard stock sizes include 6.2′ x 9′, 9′ x 18′, 8′ x 24′, and others.

- Detailed installation guides: Downloadable documentation covering site preparation, compaction specifications, panel connection, infill placement, and quality control procedures.

- Contractor connections: BaseCore can connect you with experienced installers in your region, or support your chosen contractor with technical guidance.

- Ongoing support: Questions during installation? Call or email your project manager.

The consultation is free and typically takes 15–20 minutes. You’re not committed to purchasing anything.

When support matters most: The buyer on a Houzz forum who asked about using Agtec geocell on a 35-degree slope driveway in Tennessee with 70 inches of annual rainfall is exactly the scenario where consultative support prevents expensive mistakes. Slope steepness, drainage volume, soil type, and vehicle loads all interact in complex ways that product-page guidelines can’t address. A 15-minute conversation with an experienced project manager could save thousands of dollars in rework.

The Warranty Comparison

Both Agtec and BaseCore offer 10-year warranties, but the coverage differs in important ways.

Agtec’s Warranty

Agtec’s published warranty language (from agriculturesolutions.com): “Agtec LLC warrants each Geocell section to be free from defects in materials and workmanship at the time of manufacture. Agtec LLC’s exclusive liability under this warranty or otherwise will be to furnish without charge any section which proves to be defective under normal use and service during the 10-year period.”

The warranty then explicitly disclaims all other warranties: “AGTEC LLC MAKES NO OTHER WARRANTIES, EXPRESS OR IMPLIED, WRITTEN OR ORAL, INCLUDING, BUT NOT LIMITED TO, ANY WARRANTIES OR MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE.”

This covers manufacturing defects — if the product arrives damaged or the welds are defective out of the box. It does not warrant the product’s fitness for any particular application.

BaseCore’s Warranty

BaseCore’s warranty covers product performance and seam strength for 10 years. Full details are published at basecore.co/warranty. The warranty specifically addresses seam integrity — the failure mode most likely to affect long-term geocell performance.

The distinction: Agtec warrants that the product was manufactured correctly. BaseCore warrants that the product and its seams will perform for 10 years.

Which Product Is Right for Your Project?

Rather than telling you one product is universally better, here’s an honest framework for deciding based on your actual project needs.

Agtec Geocell May Be the Right Choice If:

- Your project is small-scale (under 500 square feet) and straightforward — a garden path, a small shed foundation, a light-duty erosion control patch

- You’re a DIY homeowner comfortable making your own specification decisions

- The surface will support only foot traffic, light vehicles (passenger cars), or static lightweight structures

- You don’t need custom panel sizing, project consultation, or installation support

- Budget per panel is your primary decision driver and you’re less concerned with published performance data

- You’re buying through Amazon or another retail channel and value the convenience of that purchasing process

BaseCore Standard May Be the Right Choice If:

- Your project involves regular vehicle traffic (passenger cars, SUVs, light trucks)

- You need a residential driveway, light commercial parking area, or moderate slope stabilization

- You want published specification data and ASTM-tested performance values

- You value project consultation to confirm you’re specifying the right system

- You want multiple color options (black, green, beige) for aesthetic matching

- You’re looking for a proven product backed by a warranty that covers seam strength

BaseCore HD Is Likely the Right Choice If:

- Your project involves heavy vehicles — delivery trucks, semi-trailers, heavy equipment, fire apparatus

- You’re building commercial or industrial surfaces — truck parking, oil and gas access roads, mining operations, construction staging

- You need maximum load distribution with the option to use shallower cell depths (reducing excavation and fill costs)

- Your project involves steep slopes (2:1 or steeper) or high-velocity water channels

- Published seam peel strength, ESCR data, and double-welded seam construction give you the engineering confidence to specify the product

- You need custom panel sizing to minimize waste on large-scale projects

- You want a dedicated project manager to support your team from specification through installation

What This Looks Like in Practice: Scenario Comparisons

Scenario 1: 200-Square-Foot Garden Path

An Agtec 2-inch geocell from their website will handle this just fine. The loads are minimal (foot traffic), the area is small, and the installation is straightforward. You don’t need project consultation for a garden path. Buy the product, lay it down, fill it with decorative gravel or mulch, and you’re done.

Scenario 2: 2,000-Square-Foot Residential Driveway

Now the stakes increase. Your driveway handles daily passenger vehicle traffic plus periodic delivery trucks (UPS, FedEx, Amazon vans weigh 10,000–16,000 pounds loaded). You need the surface to last 15–20 years without major maintenance.

A 4-inch BaseCore standard geocell gives you published performance data, proper specification guidance (your project manager will confirm the right depth and recommend #57 crushed stone with fines instead of the 3/8″ gravel Agtec recommends), and a warranty that covers seam strength. The consultation ensures you don’t underspecify and end up with a failed driveway in three years.

Scenario 3: 40,000-Square-Foot Commercial Truck Parking Lot

This is where the comparison diverges most dramatically. A 40,000-square-foot truck lot handling loaded semi-trailers at 80,000 pounds requires engineered specifications, proper cell depth selection (6–8 inch BaseCore HD), heavy-duty geotextile fabric (6–12 oz non-woven), appropriate aggregate base preparation, and professional installation.

Agtec’s product page describes their 8-inch geocell as suitable for “heavy-duty industrial applications, including heavy-duty access roads, logging roads, heavy equipment areas, road base reinforcement.” But the product page doesn’t provide the seam strength data, ESCR testing results, or engineering support needed to confidently specify a system for this application. There are no project managers to consult, no custom panel sizing to reduce waste on a 40,000-square-foot project, and the warranty explicitly disclaims fitness for any particular purpose.

BaseCore HD with double-welded seams, 7,000-hour ESCR, published seam peel strength, dedicated project management support, custom panel sizing, and a warranty covering product and seam performance is engineered and supported for exactly this application.

Getting Started: Your Next Step

If you’ve been searching for Agtec geocell and this comparison has raised questions about which product is right for your project, the simplest next step is a conversation. BaseCore’s project managers provide free consultations — typically 15 to 20 minutes — where they review your application, loads, site conditions, and timeline, then recommend the right system with transparent pricing.

No commitment. No pressure. Just the information you need to make a confident decision.

Visit basecore.co/quick-basecore-quote/ to request a consultation, or call 888-511-1553 for phone support. You can also email site photos and project details to start the conversation asynchronously.

If you decide Agtec is the right fit for your specific application after reviewing the specifications, that’s a perfectly valid choice for the projects where their product performs well. The goal of this comparison is to help you make an informed decision — not to tell you what to buy.

Frequently Asked Questions

Are Agtec geocells and BaseCore geocells the same size?

Agtec geocells share the same cell dimensions (12.6″ x 11.3″) as BaseCore standard. However, BaseCore HD cells are significantly smaller at 8.5″ x 7″, providing roughly 40% tighter confinement per cell — a meaningful performance difference under heavy loads.

Does Agtec publish seam peel strength data?

Based on publicly available product listings on agtec.com and agriculturesolutions.com as of February 2026, Agtec publishes tensile strength values but does not publish seam peel strength per ASTM D6392 testing. BaseCore HD publishes 88 lbf/in minimum seam peel strength with 190 lb long-term performance.

Can I use Agtec geocell for a commercial parking lot?

Agtec lists their 4-inch geocell for “parking areas” and their 6-inch for “equipment parking.” However, commercial lots with regular truck traffic benefit from the tighter cell confinement, thicker walls, double-welded seams, and engineering support that BaseCore HD provides. Evaluate based on your specific vehicle loads and performance expectations.

Which geocell is better for steep slopes?

For slopes steeper than 2:1, BaseCore HD’s smaller cell size provides tighter infill confinement against gravitational forces. BaseCore also offers dedicated slope-specific guidance through their project managers and published selection guide, including anchoring recommendations and geotextile specifications by slope steepness.

Do both products offer a 10-year warranty?

Yes, but the coverage differs. Agtec’s warranty covers manufacturing defects and explicitly disclaims fitness for any particular purpose. BaseCore’s warranty covers product and seam strength performance for 10 years. Full BaseCore warranty details: basecore.co/warranty.

Helpful Resources

- BaseCore product specifications: basecore.co/basecore-geocell/ and basecore.co/basecore-geocell-hd/

- BaseCore selection guide: basecore.co/geocell-selection-guide/

- Request a free consultation and quote: basecore.co/quick-basecore-quote/

- Warranty details: basecore.co/warranty/

- Phone support: 888-511-1553

- Agtec geocell product pages: agtec.com/ground-reinforcement/geocells

This article compares publicly available product information from Agtec (agtec.com, agriculturesolutions.com) and BaseCore (basecore.co) including product listings, specification sheets, warranty documentation, and published technical data. Agtec specifications are sourced from their product pages accessed in January–February 2026. BaseCore specifications are sourced from their published product data, Universal Product Comparison documentation, and Selection Guide (BSC-1). Testing references include ASTM D5199, ASTM D6392, ASTM D1505, and ASTM D1693 standards. Where specifications are described as “not published,” this reflects the absence of that data point from the manufacturer’s publicly available documentation at the time of writing. This comparison is intended to help buyers make informed decisions and does not constitute engineering advice. Verify all specifications with the respective manufacturers before making purchasing or specification decisions for your project.